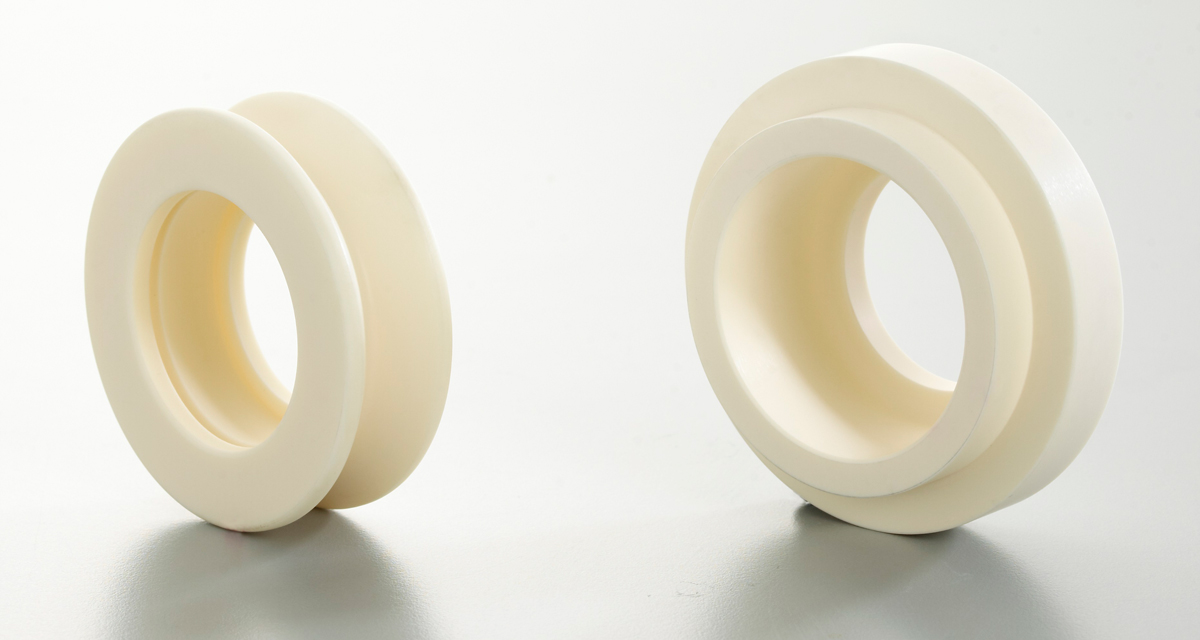

Aluminium Oxide

(氧化鋁)

Highly Durable, Resistant to Wear, Exceptional Heat Conduction

Aluminium Oxide is a raw material used in the production of advanced ceramics. In the process of oxidization, oxygen molecules form a powerful bond with the aluminium, making aluminium oxide the hardest of all oxides.

It can be used in the production of mechanical seals, bearings, abrasives, grinding wheels, molds, cutting tools and synthetic gemstones.

Aluminium oxide is a highly stable compound and highly resistant to corrosion from salts, alkalines and acids. It can be used in the manufacture of thermocouple protection tubes, boiler tubes, crucibles and fire retardant material.

At the same time, aluminium oxide is a good electrical insulator and will not become worn out from contact with electricity.

It can be used in the production of mechanical seals, bearings, abrasives, grinding wheels, molds, cutting tools and synthetic gemstones.

Aluminium oxide is a highly stable compound and highly resistant to corrosion from salts, alkalines and acids. It can be used in the manufacture of thermocouple protection tubes, boiler tubes, crucibles and fire retardant material.

At the same time, aluminium oxide is a good electrical insulator and will not become worn out from contact with electricity.

Replacing metal machine components with aluminium oxide components strengthens the system against rust, erosion and deformation. Not only the semiconductor industry, but increasingly other industries as well are adopting the use of aluminium oxide to improve efficiency and reduce operational costs.

Aluminium Oxide Related Data

| Main component | 99%Al2O3 | S-SiC | ZrO2 | Si3N4 | TC | ||

| Physical Property | Density | g/cm3 | 3.90 | 3.1 | 6 | 3.2 | 14.55 |

| Water Absorption | % | 0 | 0.1 | 0 | 0.1 | – | |

| Sinter Temperature | °C | 1700 | 2200 | 1500 | 1800 | – | |

| Mechanical Property | Rockwell Hardness | HV | 1700 | 2200 | 1300 | 1400 | – |

| Bend Strength | kgf/mm2 | 3500 | 4000 | 9000 | 7000 | 7000 | |

| Compression Intensity | Kgf/mm2 | 30000 | 20000 | 20000 | 23000 | 23000 | |

| Thermal Property | Maximum working temperature | °C | 1500 | 1600 | 1300 | 1400 | 1400 |

| thermal expansion coefficient 0-1000°C | /°C | 8.0*10-6 | 4.1*10-6(0-500°C) | 9.5*10-6 | 2.0*10-6(0-500°C) | 2.0*10-6(0-500°C) | |

| 5.2*10-6(500-1000°C) | 4.0*10-6(500-1000°C) | 4.0*10-6(500-1000°C) | |||||

| Thermal Shock resistance | T(°C) | 200 | 250 | 300 | 400-500 | 400-500 | |

| Thermal Conductivity | W/m.k(25°C | 31 | 100 | 3 | 25 | 25 | |

| 300°C) | 16 | 100 | 3 | 25 | 25 | ||

| Electrical Property | Resisting rate of Volume | ◎.cm | |||||

| 20°C | >1012 | 106-108 | >1010 | >1011 | >1011 | ||

| 100°C | 1012-1013 | – | – | >1011 | >1011 | ||

| 300°C | >1012 | – | – | >1011 | >1011 | ||

| Insulation Breakdown Intensity | KV/mm | 18 | semiconductor | 9 | 17.7 | 17.7 | |

| Dielectric Constant (1 MHz) | (E) | 10 | – | 29 | 7 | 7 | |

| Dielectric Dissipation | (tg o) | 0.4*10-3 | – | – | – | – | |

Aluminium Oxide Application Areas

Main Uses For Aluminium Oxide

| Application Environment | Applications | Qualities | |

|---|---|---|---|

| Petrochemical | High-Temperature High Pressure Corrosive Abrasion |

Bearings Mechanical Seals Bearings Valve Plates Ball Valves Nozzles Pipeline Lining Thermocouple Protection Tube |

Wear Resistant Corrosion Resistant Thermal Shock Resistant High Strength Air Impermeability |

| Textile | Grinding High-temperature High Speed |

Friction Slice Molds |

Wear Resistant Thermal Shock Resistant High Strength |

| Water Hardware | Grinding | Water Faucet | Wear Resistant |

| Other Industries | Insulation High Pressure Insulation High Temperature Insulation |

Voltage Insulator Insulator Protector Insulator Subsidies |

Highly-Insulated |

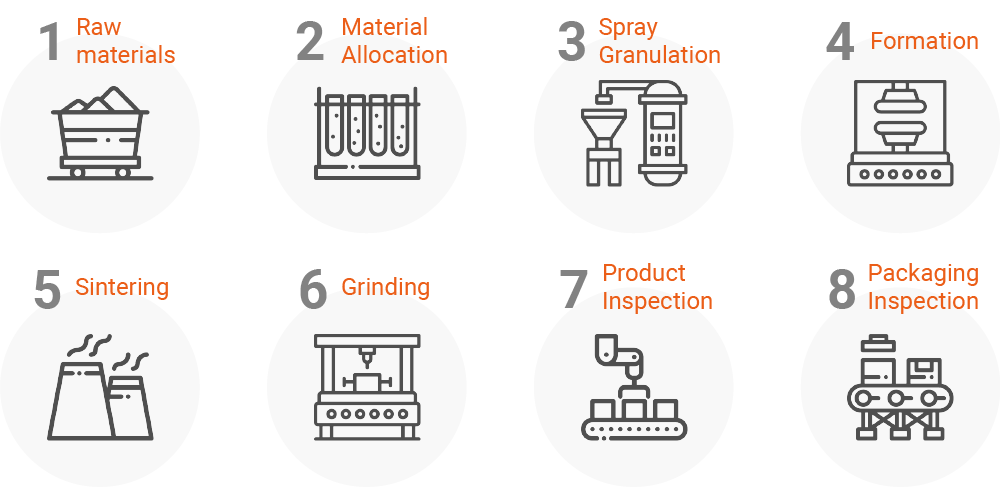

CM Advanced Ceramics - Aluminium Oxide Standard Production Process

As a specialized manufacturer with over 30 years invested in the research and development of applications for Sintered Silicon Carbide, Aluminium Oxide and Partially Stabilized Zirconia, CM Advanced Ceramics is able to produce a wide variety of precision ceramic products customized to our clients’ needs.

We employ a vertical integration approach to manufacturing, controlling all stages from material acquisition to production. Our manufacturing process adheres to ISO9001 standards and follows strict quality control procedures to ensure a long life cycle for all of our products. At the same time, we possess the ability to produce our own molds. This gives us great flexibility in mold design and allows us to quickly and accurately produce molds that meet our client’s needs, all while reducing production costs.

We happily share profits with our clients who can enjoy discounted quotes for the first order. In these ways we help open up new business opportunities for our clients who in turn can enjoy even greater profit. If you are looking for a NEW manufacturer, please contact with us RIGHT NOW.